Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

Custom Screw Services: Meeting Mark’s Special Requirements

Background

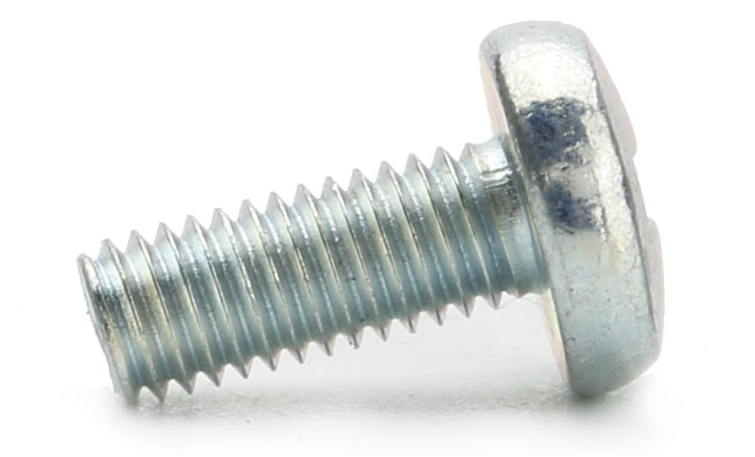

In the global custom screw market, customer demands are becoming increasingly diverse and complex. The ability to quickly and accurately understand and meet these needs is a key factor that sets us apart from the competition. Recently, our company received an inquiry from Mark, a client in the United States. He requested a custom screw—binding head screw Phillips slotted head undercut—with the additional requirement that the screws pass a salt spray test of more than 500 hours.

This custom request not only required strict specifications for the binding head screw Phillips slotted head undercut’s appearance but also demanded high standards for its corrosion resistance and material strength. Despite the complexity of the request, our sales representative, Panny, responded promptly and professionally, providing Mark with two feasible solutions, which ultimately earned high praise from the customer.

The Importance of Accurately Understanding Customer Needs

When Mark sent us his custom request, he specifically mentioned that he needed binding head screw Phillips slotted head undercut that could withstand a salt spray test lasting 500 hours or more. For those unfamiliar with the technical terms of the screw industry, such a request might be difficult to understand immediately. However, Panny, drawing on her extensive experience and keen insight into market demands, quickly grasped Mark’s needs and took swift action.

In her response, Panny sent Mark a picture of a binding head screw undercut to confirm if this was the type of binding head screw Phillips slotted head undercut he was describing. This move was crucial as it ensured both parties were on the same page early in the communication process, preventing potential misunderstandings or errors later.

Mark was pleased to see the image, confirming that it was indeed the binding head screw undercut he needed. He appreciated Panny’s quick and accurate understanding of his needs, acknowledging our professionalism and thanking her for her attentive service. This set a solid foundation for the discussions that followed.

Providing Multiple Feasible Solutions

After confirming the appearance requirements of the binding head screw, Panny immediately provided Mark with two material options that could meet his requirement for a 500-hour salt spray test:

Recommendations for High-Strength Applications

After learning about the two material options, Mark requested further information, specifying that the screws needed to withstand high-strength applications and that the surface should be black. In response, Panny recommended the second option—carbon steel with a black Dacromet coating.

Panny explained in detail why carbon steel is more suitable for high-strength applications: carbon steel has high hardness and strength, and when treated with Dacromet, the binding head screw Phillips slotted head undercut’s surface corrosion resistance and appearance are significantly enhanced. This treatment not only meets the 500-hour salt spray test requirement but also ensures the screw binding head’s stability in high-strength environments.

Additionally, Panny proactively inquired about the specific strength grade required for the screw binding head. Mark responded that he needed the screws to be at least grade 10.9 and asked if we could provide hardness and salt spray test reports to ensure the screws meet his requirements.

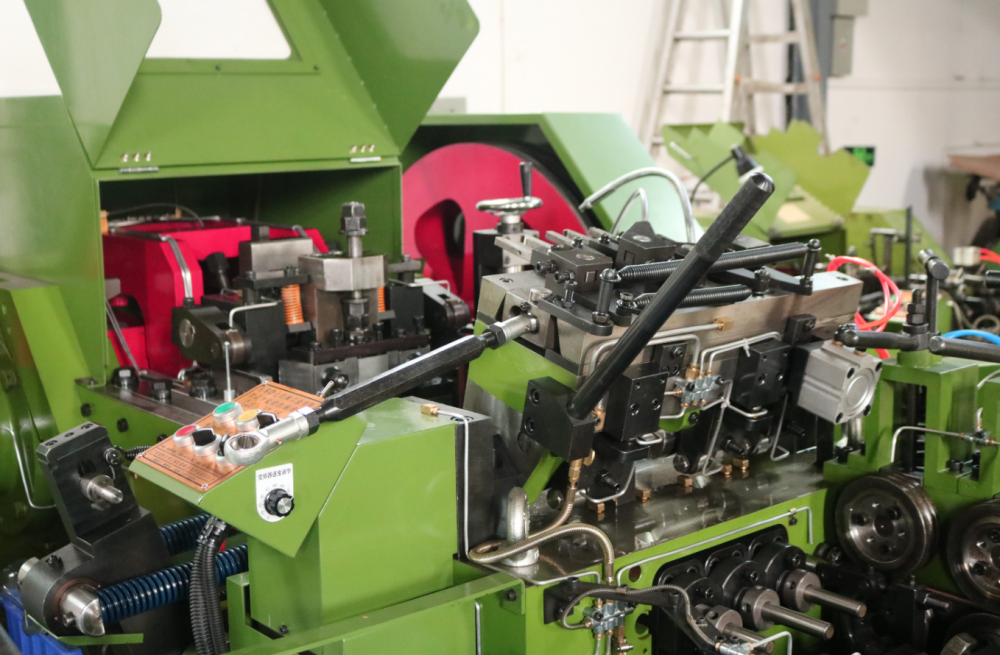

Comprehensive Testing Equipment and Services

Our factory is not only a professional binding head screw Phillips slotted head undercut manufacturer but is also equipped with advanced hardness testing and salt spray testing equipment, fully capable of meeting Mark’s requirements. Through this equipment, we can conduct rigorous quality checks on every batch of screw binding head products we produce and provide detailed test reports, ensuring reliable quality assurance for our customers.

Upon learning about our testing capabilities, Mark expressed increased confidence in our services. He noted that these reports would provide peace of mind during the subsequent product inspection and application processes.

Cost-Saving Suggestions

After providing Mark with a detailed quote, Panny continued to offer value-added services. She presented two different binder head screw head designs and asked Mark which head shape he preferred. Panny also informed Mark that selecting the second binding head screw Phillips slotted head undercut head design would require an additional mold fee of approximately $90 on top of the first design.

First:

Second:

Considering Mark’s potential need to save on costs, Panny suggested that he choose the first head shape, as this option avoids the additional mold cost without compromising the screw’s performance. However, Panny also mentioned that if Mark had higher aesthetic requirements for the screws, the second head shape would better meet his needs.

This suggestion left Mark very satisfied. He not only thanked Panny for her professional advice but also appreciated her help in understanding more about the cost structure. Mark stated that Panny’s advice allowed him to control costs more effectively while maintaining the binder head screw’s performance, which was very helpful to him.

Conclusion and Outlook

Throughout the entire process, Panny’s outstanding expertise and meticulous service successfully helped Mark solve a series of issues related to custom screw production. From accurately understanding customer needs to providing multiple feasible solutions and offering cost-saving suggestions, Panny’s performance earned high praise from Mark.

For other customers, if you find it challenging to communicate your needs for binding head screw Phillips slotted head undercut with other screw suppliers or if you are unable to find satisfactory solutions, feel free to contact us.

We are not only a professional binding head screw manufacturer but also have extensive industry experience and a skilled technical team that can provide high-quality custom screws according to your specific requirements. At the same time, we strive to offer cost-effective solutions, ensuring that we maximize your production savings without compromising product quality.

Consult Your Screw Customization Experts

As your screw customization experts, we are committed to helping you save communication costs and time, offering binder head screw products that meet your quality standards. With our experienced technical team and advanced testing equipment, we ensure that every product meets the high standards set by our customers.

We will also do our utmost to provide cost-effective production solutions, helping you maintain an edge in the competitive market. No matter how complex your requirements are, we can find the optimal solution for you. We look forward to working with you to create greater value together.

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

8 月-20-2024

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com