Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

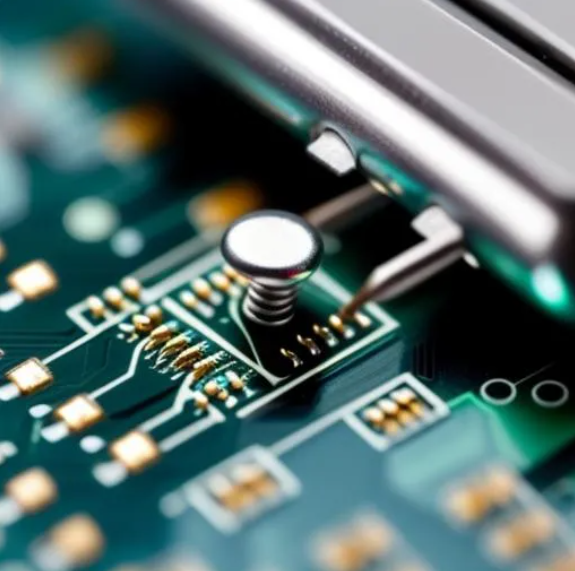

We ignore small screws all the time, but they make a HUGE difference when precision matters. If you have the wrong screw, it could cost you in a big way because things won’t work correctly, or it might cause major damage to something very sensitive. Don’t discount the importance of small screws to get the ultimate performance out of your system.

Small screws are crucial components in industries like electronics, medical devices, and precision machinery. Their accurate dimensions and durable materials ensure structural integrity, supporting the efficient functioning of small and complex systems.

Picking out the right small screw gets down to understanding what the application demands are and what the material properties are. Let me show you how these things are defined, how you use them, and why small screws are essential in almost every industry you can think of.

What makes small screws so important in high-precision industries?

Small things are very underappreciated. Yet, they are CRITICAL in your complex piece of machinery. If you have the wrong screw, even if it’s off by one thousandth of an inch, you could screw up the whole thing and have a machine down or some very expensive repairs.

Small screws provide high precision in fastening, ensuring stability and preventing system failure in high-precision industries like aerospace, electronics, and medical devices. Their design allows them to hold delicate components securely, maintaining performance without adding bulk. This ability to support fine-tuned operations without compromising the integrity of a system is essential in environments where precision is paramount.

What are small screws called, and what sizes are available?

It’s easy to get confused with screws, especially when you start dealing with all the different kinds. Then, you start getting into highly specialized applications where size and function start counting. Because you picked the wrong size screw, you can’t get things together, now you’ve got a failure or the strength goes to hell or whatever else.

Small screws are often referred to as “mini screws”, “tiny screws”, “precision screws”, “miniature screws” or “micro screws,” depending on their size. Tiny screws typically range between M1 and M3 in diameter. These screws are used for delicate applications like electronics, watches, and eyeglasses, where precision is key. The size of mini screws can vary, but they are generally smaller than standard screws and designed for precision fastening in small, intricate components.

What are mini and micro screws used for?

Not every screw can give you the support you need when your little bitty device also needs precision and security. These products suffer from the wrong screws. Think about electronics and little tiny medical devices with loose connections, weak assemblies, and malfunctioning pieces.

Mini screws are commonly used in electronics, watches, and eyeglasses, where compact fastening is necessary for tight spaces. Micro screws, even smaller, are essential in high-precision applications such as medical devices, hearing aids, and intricate mechanical assemblies where ultra-small dimensions are critical. These screws allow engineers to create products that are both lightweight and durable without sacrificing the structural integrity required for optimal performance.

What are 5 different types of small screws, and how do you screw them in?

There are so many different screws out there that deciding which one to use seems almost impossible. But guess what? Use the wrong one, and all of a sudden you’ve got a big issue getting your stuff together and it’s ruined or not going to work as expected.

The five most common types of small screws include:

1.Flat-head screws: Designed to sit flush with the material surface.

2.Round-head screws: Offer a more rounded, raised finish.

3.Pan-head screws: Provide a wide, flat surface for a secure grip.

4.Hex-head screws: Feature a hexagonal head, often used with a wrench.

5.Socket-head screws: Used in applications requiring high torque.

Every screw needs some specialized tool to drive it. Small screws might mean a small precision screwdriver, right? So you need precision tools that let you control the torque on the screw. You don’t want to strip out the head or ruin whatever it is the screw is going into because you put too much torque on it. So, what do you need to do what you want to do in a small and delicate environment?

What tools are used for handling and unscrewing tiny screws?

That’s another thing. Talk about frustrating and a waste of your time. I’ve lost a part because I’ve stripped out the head or something. You know what I’m talking about! Anytime you do that when you’re trying to work on small stuff, it just drives you absolutely bonkers. And, if you don’t have the right tool to remove the screw, then you’re toast.

Precision screwdrivers are the most commonly used tool for handling small screws, and many are magnetic to prevent tiny screws from getting lost. For unscrewing tiny screws, you can also use tools like tweezers, precision pliers, or specialty screwdrivers designed for delicate operations. Some screwdrivers even come with interchangeable heads to fit different screw types, offering versatility for various projects.

Conclusion

If you make or use a high-precision machine, you want to keep it that way. That little tiny screw does just that. A super-tiny screw does that for you. All you’ve got to do is figure out where they are. Then, talk to whoever you need to talk to and buy the right ones to screw whatever it is you’re screwing.

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

9 月-24-2024

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com