Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

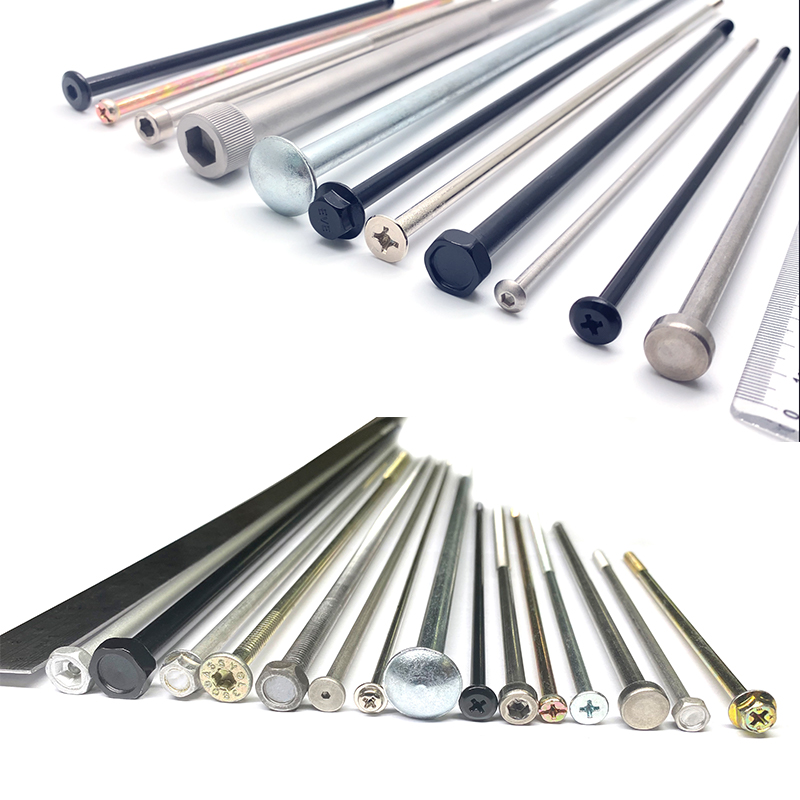

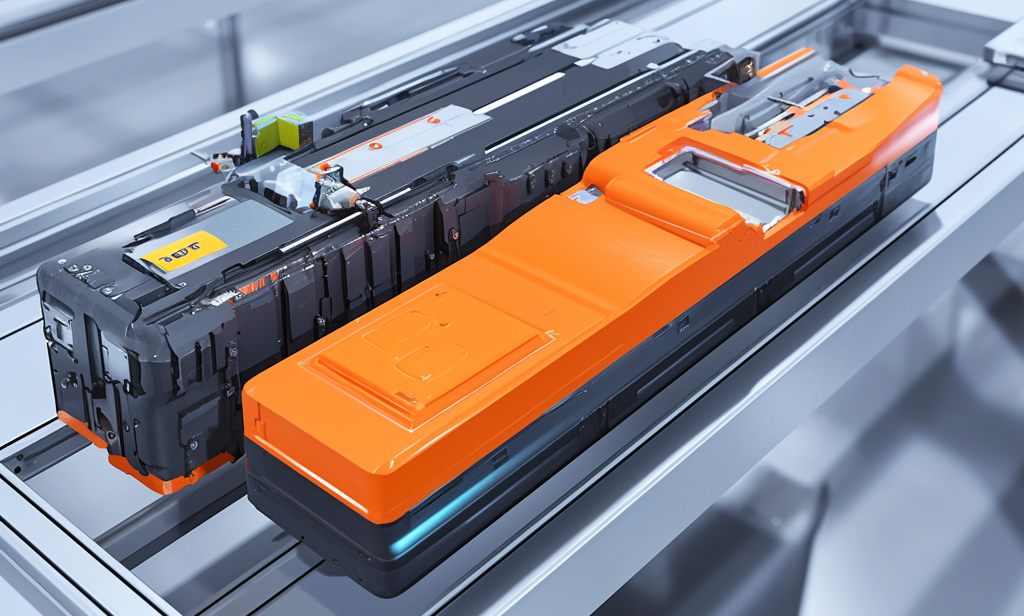

New energy battery modules are increasingly complex, and the demand for reliable, high-strength fasteners is greater than ever. Our long screws provide the precise, stable connections you need for these large assemblies, ensuring safety and durability in demanding applications.

Long screws are crucial in new energy battery modules because they ensure stable, reliable connections in large battery assemblies. Their length helps handle the size and complexity of these modules, improving durability and safety.

Understanding how long screws function in battery modules will help you quickly see how important they are for keeping the integrity and safety of new energy solutions.

What Specific Role Do Long Screws Play in Battery Module Assembly?

Battery modules have to be fastened down well in order to keep them from shaking and to keep loose connections from impacting their performance. Long screws have the depth and strength that allows you to fasten the multiple layers of a battery module for a secure fit that doesn’t move around and that meets the electrical performance you need.

Long screws are used to fasten multiple layers within a battery module. Due to their length, they can penetrate deeper and hold larger components more effectively than standard screws. This is crucial because battery modules, especially in new energy vehicles, often involve stacking multiple cells and components. Stability is key to preventing short circuits, avoiding overheating, and ensuring safety under vibration and other mechanical stresses.

Why Are Long Screws Preferred Over Other Types of Fasteners for Battery Modules?

Losing fasteners or having fasteners break will lead to module failure, which affects safety and also shows itself in performance, especially in tough applications like electric vehicles or energy storage systems. The reason long screws are used in battery modules is because they offer awesome precision, they’re tough and can handle large, layered structures without losing their grip or letting something fall apart.

Compared to other fasteners, long screws provide greater flexibility when dealing with thick or multi-layered battery modules. Their extended length allows them to secure all layers in a single fastening operation, reducing the need for additional components like clamps or support structures. This reduces assembly complexity and ensures even pressure distribution across the entire module, enhancing both mechanical stability and electrical reliability.

How Do Long Screws Contribute to the Safety and Longevity of New Energy Battery Modules?

Poor fastening on a bolt can lead to corrosion of or failure in battery systems, leading to risks like leakage, short circuits, or reduced energy efficiency. Long screws greatly enhance the safety and longevity of the battery modules because you can help fasten them down tightly so they don’t rattle loose and develop problems due to mechanical stresses (e.g. cell shifting) or electrical failure.

Safety is a top priority in battery modules, especially in applications like electric vehicles or renewable energy storage systems. Long screws contribute to this by offering strong, vibration-resistant fastening, minimizing the risk of internal damage due to shifting or impact, which could lead to dangerous outcomes such as short circuits or fire.

Another [Big Thing] to keep you safe and help you have a happy long life is the strength of the screw. All battery modules need high strength screws due to the mechanical stress involved, especially in tough working environments. However, here is the [Big Thing] few people can do: they make long screws, such as those used in battery modules, in the tens of millions at strengths higher than an 8.8 grade. The problem is once a screw gets longer, they are having a tough time getting the tensile strength to stay up. The longer a screw is, the harder it is to be strong without it bending or breaking (falling over) when it is heat treated.

This is why Shi Shi Tong is so incredible. We can make long screws up to 500mm that will stay high enough grade to meet the 12.9 strength level. For longer screws over 500mm, we still keep enough strength of at least an 8.8 grade. This is a big deal for you in safety and performance. We keep our screws strong so they don’t bend over like a two-dollar watch, even in extended or high stress applications, which does a lot to add to the integrity and reliability of the battery module.

What Materials and Coatings Are Best for Long Screws in Battery Modules?

Why is material choice crucial to this story? Because if you pick the wrong material it will corrode, fall apart, and make your battery worthless. The perfect material for the screws is stainless steel or a special coating offering you corrosion resistance and enough strength to help your battery survive whatever you throw at it. These screws don’t care if they’re stuck in a harsh environment.

Long screws in battery modules need to withstand various environmental factors, including heat, moisture, and potential chemical exposure. Stainless steel is a popular choice due to its corrosion resistance and strength. Additionally, surface treatments like zinc plating or other coatings can further enhance the screw’s durability and resistance to oxidation, ensuring long-term performance even in challenging conditions like high temperatures or humid environments.

Conclusion

Long screws are a key part of the assembly of new energy battery modules. They give you the strength, the durability, and the precision to hold all of this together in a safe, secure, and long-lasting fashion. You need to keep that multi-million dollar machine on the road and running at 100% day after day!

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

10 月-18-2024

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com