Metric Titanium Screws Inspection

In order to ensure the quality of the metric titanium screws when manufacturing the screws, we will randomly check some samples for inspection. Then what are the inspection contents of the screws:

★ Appearance:

☆ The surface should be complete without cracks, wear and tear.

☆ The metal is not oxidized.

☆ The gloss of the coating should be even. There can be no blistering or cracking.

☆ The surface coating should not fall off.

☆ The surface should be neat and free of stains.

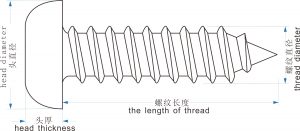

★ Size:

☆The measured tolerances of each part are consistent with the drawings.

☆ The head meets the drawing requirements or is consistent with the sample.

☆The head and the rod of the metric titanium screws are perpendicular.

★Material:

☆Materials meet the drawing requirements.

★Package protection:

☆The outer packaging is not allowed to be damaged, deformed or damp.

☆ If the customer has a label, check whether the label is consistent with the customer’s request.

☆ Whether the packaging requirements are the same as those requested by the customer.

★ Actual assembly:

☆ Test with a screwdriver or screwdriver to see if it can be tightened. See if there will be a slippery batch or a failure to enter.

☆ Use nuts and metric titanium screws for assembly. Do not tighten or install them.

☆ Test the actual torque of the metric titanium screws to meet the customer’s requirements.

☆ To be able to pass the rules.

The above is the general requirement for metric titanium screws inspection. If you want to know more about screw fasteners, please feel free to contact us. Kalyn@szsst88.com