Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

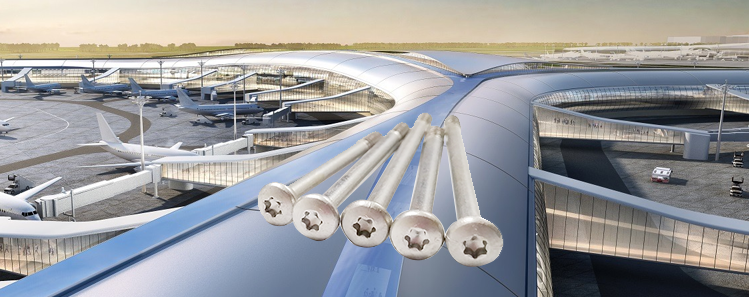

In the field of fireproof engineering, the selection of fasteners is crucial. Especially when the project involves projects with high safety standards such as fireproof glass, fasteners such as screws must not only be able to withstand high temperatures but also have excellent mechanical strength and corrosion resistance. Mr. Yang’s company focuses on fireproof glass and related fireproof engineering. To use suitable fasteners in the project, Mr. Yang decided to customize a batch of 410 stainless steel pan head screw and contacted our Shi Shi Tong screw manufacturer.

Project Background

Many materials in fireproof engineering need to undergo rigorous safety tests, including fasteners for installing fireproof glass. Since the quality of fasteners directly affects the installation stability and long-term durability of fireproof glass, choosing the right screw material and specifications has become the key.

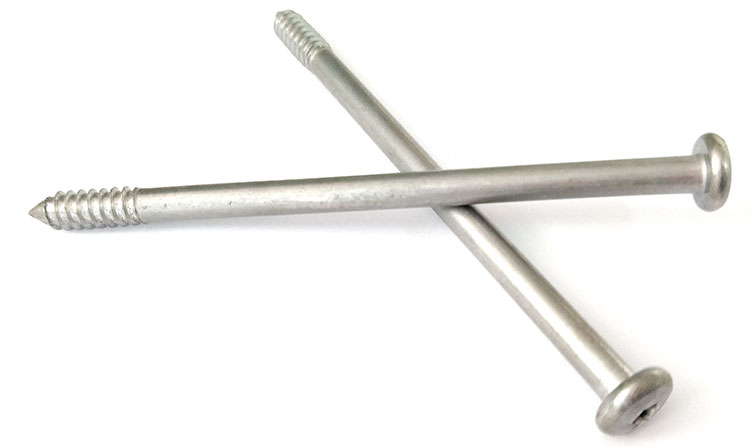

Through a friend’s recommendation, Mr. Yang found us and hoped to customize a batch of self-tapping screws made of 410 stainless steel. This batch of pan head screw has a diameter of 6mm and a length of 70mm, 85mm, 115mm, and 120mm respectively. The head is required to be a pan head torx screw, and the hardness is particularly needed to reach 45HRC or above.

Characteristics of pan head screw

First, we need to understand the characteristics of pan head screw. Compared with ordinary stainless steel, 410 stainless steel has better strength and wear resistance, especially after proper heat treatment, its hardness can reach a higher standard. Therefore, 410 stainless steel is widely used in occasions that require high hardness and corrosion resistance, such as fire protection systems in construction projects, marine equipment, and chemical equipment. However, 304 and 316 stainless steel cannot be heat treated, and the hardness of stainless steel screws cannot be improved by heat treatment.

The biggest advantage of 410 stainless steel material is that it can provide good corrosion resistance while having strong hardness and wear resistance. This makes it one of the ideal screw material choices in fire protection projects. This material can not only maintain stable performance in high-temperature environments, but also can be used for a long time in humid and highly corrosive environments.

Confirmation of customized needs

Mr. Yang has a very clear demand for customized pan head screw. In addition to specific requirements for the specifications and hardness of the pan head torx screw, Mr. Yang also hopes that the design of the pan head screw can meet the installation requirements of the fire protection project to the greatest extent. To ensure that there are no errors in the production process, Miss Song had a detailed communication with Mr. Yang and confirmed the key technical parameters of the pan head screw one by one.

The rod diameter of the half-thread self-tapping screw

What Mr. Yang needs is a half-thread self-tapping screw. The characteristic of the self-tapping screw is that it does not need to be pre-drilled on the installation material in advance, and the self-tapping screw itself can directly form a thread by rotation. This kind of self-tapping screw is often used in soft materials such as wood and plastic. In Mr. Yang’s fire protection project, it is mainly used to connect the glass frame with the fireproof glass.

When customizing half-thread screws, the rod diameter is one of the most important parameters. The rod diameter not only affects the strength of the screw, but also determines the tightening effect of the pan head torx screw during assembly.

To prevent Mr. Yang from not knowing which size she was talking about, Miss Song sent a drawing of a half-thread screw and marked where the rod diameter was.

Many customers may overlook the importance of the shank diameter when customizing half-thread screws, but for screw manufacturers, this parameter directly affects whether existing molds can be used. If there is no ready-made mold, a new mold must be customized, which will increase production costs. Therefore, confirming the shank diameter is crucial to the entire production process.

Head design of pan head screws

Pan head torx screws are widely used on many occasions requiring high torque due to their unique head design. The torx drive can provide greater torque and reduce the possibility of thread stripping during assembly. In addition, the larger head area of the pan head screws can effectively increase the force-bearing surface and ensure more stability during installation.

When customizing pan head torx screws, the size of the head needs special attention. Conventional 6mm diameter pan head screws usually use a T30 specification torx drive, the head diameter is generally between 9.8mm and 10.5mm, and the head thickness is between 3.9mm and 4.1mm. If the head size meets this standard, screw manufacturers can use existing molds for production, thereby saving mold costs.

However, Mr. Yang mentioned in the customization that the head diameter of the pan head torx screw needs to be 2mm larger than the regular one. This non-standard size means that we have to customize the mold for this purpose. Although the cost of opening the mold has increased, this customized service can ensure that the pan head torx screw achieves the best effect in use.

Thread design of A type screw

A type screw is a kind of self-tapping screw. Its thread design enables it to be used in a variety of materials, especially suitable for softer materials such as wood and plastic. When customizing self-tapping screws, the length of the thread determines the bite effect of the self-tapping screw, and A type screws of different lengths need to be produced with different thread rolling dies plates.

Among the 4 screws customized by Mr. Yang, the thread lengths are 15mm, 18mm, 20mm, and 25mm respectively. Since different thread lengths require different thread rolling die plates, this will greatly increase the production cost. To help customers save money, Ms. Song suggested that the thread length of all A-type screws be unified to 20mm so that only one pair of thread rolling die plates needs to be customized. After communicating with the engineering department, Mr. Yang finally decided to accept this suggestion, which further reduced the production cost.

Order quantity and quotation

After confirming all the technical details, Mr. Yang finally decided to order 20,000 pcs pan head screw of each specification, a total of 80,000. We provided him with a detailed quotation based on his customization needs and production process and ensured that the corresponding material report and shipping report were provided after the production was completed. The material report can help customers confirm whether the performance of the pan head screw material meets the requirements, and the shipping report ensures that each batch of pan head screw has undergone a strict quality inspection.

Production process and process

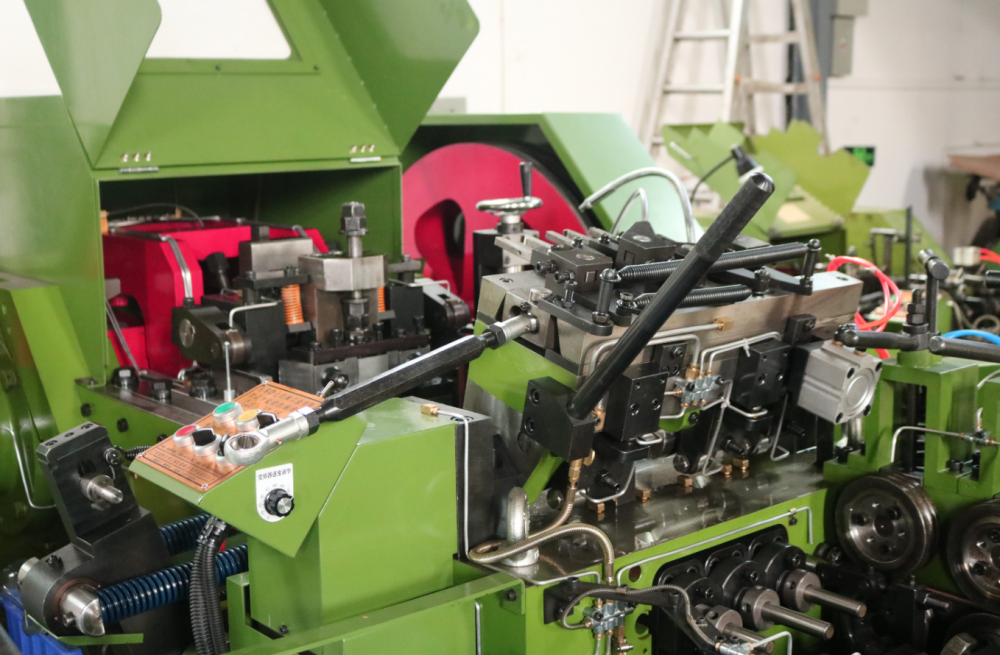

After confirming Mr. Yang’s order, we immediately started the production preparation work of pan head screw. Since this batch of pan head screw is a non-standard specification, we need to customize a special mold for it, and due to factors such as material procurement and production scheduling, the entire production cycle is expected to be 25 working days.

Material procurement

410 stainless steel is a special stainless steel material that is widely used in the fields of construction and machinery manufacturing due to its superior corrosion resistance and high strength. We need to order 410 stainless steel raw materials from suppliers to ensure that the quality of the materials meets the production requirements. Since this material is not available in the market, we need to wait for the material to arrive, which is also one of the reasons for the long production cycle.

Custom mold

Due to the special specifications of Mr. Yang’s pan head screw, especially the head size and rod diameter are different from the standard specifications, we need to customize a special mold for it. The design and production of the mold is a very delicate process, which directly determines the final molding quality of the pan head screw. After the mold is made, we also need to take the mold for trial operation, especially for multi-station machines, which need to be run in to ensure that it can be used normally in production.

Production scheduling

After the mold is ready, the production department will schedule orders according to the current order situation. Mr. Yang’s order involves multiple processes, including heading, tapping, hardening, surface treatment, etc. Each process requires strict control of time and quality to ensure that the performance of each batch of pan head screw meets customer requirements.

Hardening and surface treatment

To achieve the hardness required by Mr. Yang, the pan head screw need to be hardened after production. Hardening treatment can make the surface hardness of self-tapping screws reach more than 45HRC, thereby improving the wear resistance and tensile strength of self-tapping screws. After the treatment is completed, the self-tapping screws also need to be surface treated to increase their anti-corrosion properties and ensure that the self-tapping screws are not easy to rust during long-term use.

Order confirmation and delivery

Two days later, Mr. Yang confirmed the order after an internal discussion and sent the purchase order to us. We immediately started the material procurement and mold customization process to ensure that the production was completed within the agreed delivery period. Throughout the production process, we will strictly follow Mr. Yang’s requirements to conduct quality inspections on each batch of pan head screw and provide corresponding material reports and shipping reports.

Summary

This cooperation with Mr. Yang demonstrates the technical capabilities and service level of our Shi Shi Tong screw manufacturer. As a professional screw manufacturer, we can provide customized solutions according to the specific needs of customers. From material selection, specification design to every link of the production process, we strictly control to ensure that every 410 stainless steel screw received by the customer meets the requirements.

The process of customizing stainless steel screws is not only a test of technology and equipment, but also a reflection of accurate understanding of customer needs and efficient communication. In this cooperation, we helped Mr. Yang optimize the design of pan head screw, save production costs, and ensure the punctuality of delivery.

If you have similar stainless steel screw customization needs, please feel free to contact us. We will provide you with ideal solutions with a professional attitude and efficient service.

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

9 月-27-2024

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com