Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

Screw fasteners come in a variety of head shapes, groove types, threads, and the like. Screws consisting of different head shapes, groove shapes, threads, and sizes are also different. Screw fasteners have different head shapes and different functions. So what are the screw head types and applications?

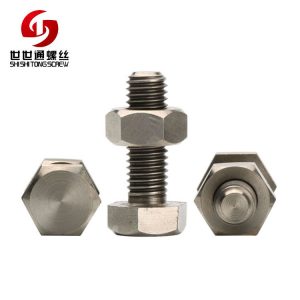

Hexagon head: It has high mechanical properties, which is easy to tighten the wrench. It can apply a large tightening torque. It is the most widely used type with different types and sizes.

The head band or the flange head has the function of a washer and a stopper to increase the pressure receiving surface and has better anti-loosening performance.

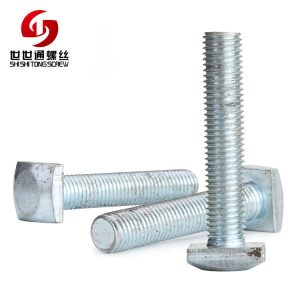

Square screw head types and applications: The head is large in size, which is convenient for the wrench to be tightened or the other parts to stop. It can apply a large tightening torque, and the pre-tightening force or the top tightening force is large, and the baldness is not easy to be screwed. It is mostly used for rough and often disassembled structures, but it is not suitable for moving parts.

Pan head: The head size is small. However, it has high strength and small space, and is often used for high-strength bolts of steel structure. When used for screws, the head has a slot or a cross slot for the tool to rotate. The slot is versatile and is used for fasteners with low strength and low torque. The head of the Phillips screw is easy to manufacture and has high productivity. Neutrality when screwing, easy to automate assembly. The strength of the cross recess is high, it is not easy to twist bald, and the appearance is beautiful.

Half round screw head types and applications: It is often used for joints where the surface of the structure is required to be smooth or restricted by other bolt heads. The square neck prevents rotation during screwing and is used for the coupling of metal parts; the large round head is used for the joint of wooden parts. . The head slot is mostly used for screws to connect the parts inside the structure.

Truss head: the height of the half round head is smaller, the outer diameter is slightly larger, and the bearing area is increased, which is mostly used for the connection and fixing of thin-walled parts and plate structures.

Countersunk head: The head can sink into the cone of the surface of the jointed part, and it is often used for the surface where the surface is required to be smooth, the appearance is beautiful, or the internal structure does not allow the bolt head to protrude. There is a square neck or cymbal under the head to prevent rotation when the nut is screwed. When used with screws, the head has a slot or a cross recess.

Raised countersunk head: The same characteristics as the countersunk head, but can increase the strength of the countersunk head and is suitable for joints with a certain axial load.

Cup head: the head is small, the inner hexagon is used for screwing, and a large tightening torque can be applied; the head can be buried in the part, the joint strength is high, and the structure is required to be compact, the shape is smooth or the joint cannot be tightened with a common wrench.

T-head: Can be fixed in the slide of the T-slot and can be moved inside the slot to adjust its position.

If you want to know more about the screw head types and applications, please feel free to contact us any time: annie.li@szsst88.com

9 月-28-2018

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com