Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

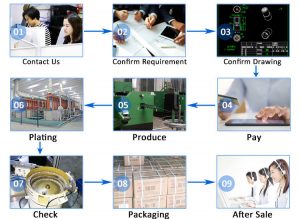

Special screw factory products from scratch, there is a process, these can also be called product production steps. Let’s take a look at these steps today.

Have you understood the eight processes of the special screw factory? If you have any questions or opinions, please contact us.

|

Skype: kalyn qin M: +86 18124507113 Tel: +86 0755-85296744 Add: No. 11, Dinghou Road, Dongfang Community, Songgang Street, Baoan District, Shenzhen, Guangdong, China

|

3 月-06-2020

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com