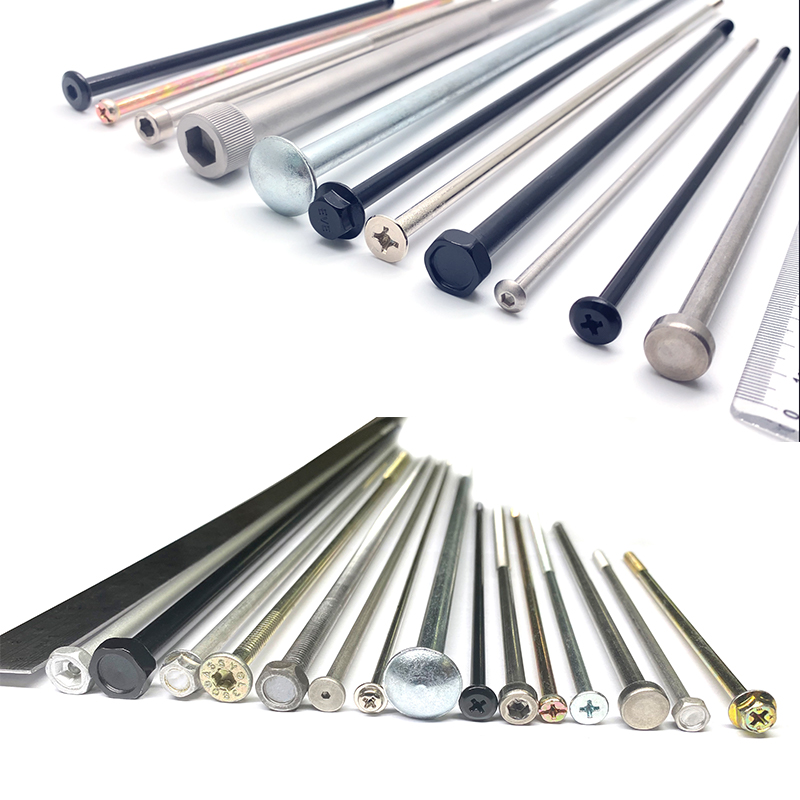

Customizing speciality machine screws saves customers a fortune in mold costs – Shi Shi Tong

Shi Shi Tong non-standard screw manufacturer received an inquiry from a customer a few days ago, saying that he wanted to make speciality machine screws. After the customer sent the drawing, he found that it was a relatively non-standard screw. The head needs to be knurled, and the middle of the stem needs to be machined.

During the conversation with the customer, we learned that the customer was manufacturing optical telescopes, astronomical telescopes, rangefinders, night vision devices, optical sights, and optical lenses. In our impression, the prices of such products are very high. The first impression given to Shi Shi Tong screw manufacturers is that the customer’s material value is very high, and we mistakenly believe that customers will also have high requirements for screws.

After receiving the customer’s drawings, Shi Shi Tong screw manufacturer thought of 2 production methods:

- Turning: If the customer has high requirements for precision and quality, it is a good choice.

- Cold heading: If the customer has a large quantity in the future, knurling the back groove of the mold opening floor machine can save costs.

Later, through communication with the customer, I learned that the customer did not understand the product and had no requirements for the precision of speciality machine screws. After confirmation through the internal engineering of Shi Shi Tong’s non-standard screw manufacturer, we asked the customer if he would accept the change to a smaller rod diameter and the sharing of our existing mold. After internal discussion, the customer agreed to change the rod diameter to a smaller diameter. After the diameter of the rod is reduced, the customer saves a lot of mold costs.

|

Skype: kalyn qin

M: +86 18818786322

Tel: +86 0755-27322278

sst@szsst88.com

Add: No. 11, Dinghou Road, Dongfang Community, Songgang Street, Baoan District, Shenzhen, Guangdong, China |