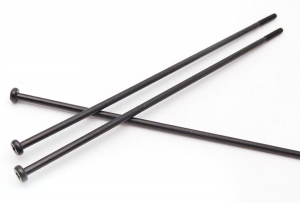

What problems do long thin screw encounter when they do quality inspection?

When the company purchased back a batch of products, it is generally someone to test the purchase of this batch of products are not qualified, there is no problem and so on. The same is true when purchasing a long thin screw, so what problems will this type of screw encounter when doing the quality inspection?

One, forming problems appear bad. There are long thin screw eccentric, the head has the mark, the explosion first class, and so on. This is because the screw manufacturer did not check or did not pay attention to the quality control will appear.

Two, rub a tooth bad. This is mainly the teeth rub in the process of the master did not use ring gauge inspection or halfway teeth plate is broken, did not pay attention to the problems caused.

Three, poor electroplating. If the quantity is very small, it means that the screw manufacturer has checked the electroplating of these long thin screw, but it has not fully inspected them, or at least some of them have been sampled and failed to notice the defective electroplating.

Four, mixing. If it is a product of a similar size, the long thin screw manufacturer may have sampled at least part of the product and not carried out a full inspection. But if the product difference is too big, the screw manufacturer may be careless in the inspection, so it will be mixed.

|

Skype: kalyn qin

M: +86 18818786322

Tel: +86 0755-27322278

annie@szsst88.com

Add: No. 11, Dinghou Road, Dongfang Community, Songgang Street, Baoan District, Shenzhen, Guangdong, China |