Tel:

+86 13143444311

Email:sst@szsst88.com

Fax:+0086-755-27322278

Address:Building 9, First Industrial Zone, Tantou Industrial City, Songgang Street, Baoan District, Shenzhen 518105, Guangdong, China

Trying to find custom long screws that are fantastic is like pulling out your hair. . . . If you don’t have the right screws, your doggone thing won’t hold together. But you don’t have to worry because when you get custom long screws, they will be exactly what you need and do everything you want them to do.

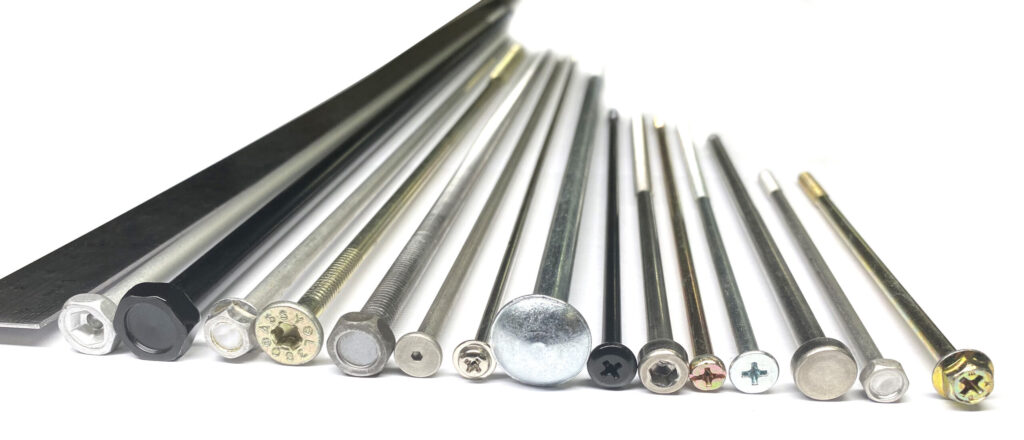

Custom long screws are critical for projects that require unique lengths, diameters, and materials. These screws deliver the strength, durability, and precision that off-the-shelf options often cannot provide, ensuring superior performance in complex or specialized tasks.

Custom long screws solve a lot of people’s problems. But why? What the heck do you do with a screw as long as my middle finger?

What Are Long Screws Called, and What Are Their Benefits?

Before we get into the bullet points about long screws, let’s talk about the naming conventions that come with these screws.

What do you call a long screw? These screws go by different names, which is a good thing; however, people tie themselves into knots and it slows down the process of getting the product they need.

Different people refer to long screws as:

Extra long screw

Infinite length screw

Super long screw

Long bolt

Extended-length screw

Custom long screws are particularly valuable for projects where precise sizing and material strength are required. They provide multiple advantages, including exact length for proper fit in specific applications, increased stability, and improved performance in high-load or heavy-duty environments. Whether the screws are used in construction, automotive, or aerospace industries, they are designed to meet the demands of complex applications where standard screws would fall short.

What Is the Longest Screw Length Available, and How Do Custom Screws Improve Efficiency?

We’ve made all sorts of different long screws over the years. You needed a long screw and what we offered wasn’t long enough. The deal with custom screws is we can make you just about any length you want. Most off-the-shelf screws are almost 12” (300mm) long. Custom long screws can be made to pretty much any length, all-thread or tapped. Primarily, these custom long screws can be for machines and equipment.

We’ve made a longer screw for a customer than we’ve ever made for somebody. That was around one and a half to two meters long. We’ve made screws as short as a couple of inches or a couple of millimeters long and over 10 feet long. Whatever length you need, we’ve done it, and you can benefit from our experience. You needed a longer screw, and you got one. That’s a difference maker for you.

That’s all the information you could ask for in 1,700 words or whatever and I squeezed it down into about 150 words. Did you get the right material? Did it work for you? Did you get the right length? Fill out the form to the right or give us a call right now to let us know about your application and how fastener supplier Shi Shi Tong can help you with your next custom long screw. Let us be your long screw company.

Having screws made to the exact specifications you need from the beginning significantly improves project efficiency. By using custom screws, you eliminate the need to modify off-the-shelf options or deal with the delays that come from finding alternative solutions. This saves time on installation and reduces the potential for costly rework. Additionally, the right length and material ensure that the screws perform as required, avoiding structural issues that may arise from using improper fasteners.

What to Do if a Screw Is Too Long?

If you have screws that are too long when you screw them in, they’ll mess up whatever you’re working on. What are your options? You can put a bolt in a vise and take a hacksaw and cut it off. You can also put some washers or spacers under the head of the bolt to keep it from going down as far. Feel free to get a little creative when fixing problems. If you’re unsure what to do, ask somebody else. But don’t do something that you know is the wrong thing to do. You’ve got better options than that.

However, trimming screws can be time-consuming and may not always result in a clean, precise fit. A more efficient solution is to avoid this issue entirely by ordering custom screws made to your exact requirements. This ensures that the screws are the right length for your application, reducing the risk of instability or structural weakness.

What Is Long Screw Damage, and How Can It Be Prevented?

Damage to extra long Screws is Common

When you use a screw too long, you can cause damage to the screw and screw the pooch. The sort of damage you see from using a screw that is too long for your application or is the wrong material for the job or you over-tighten the screw usually happens as a bent or broken screw you’re trying to loosed or fasten or it involves stripping the head off the screw . . . oh, great what are we going to do now.

The lesson here is if your situation involves damage, it comes from using the wrong screw in the first place (refer to damage above). Too long of a screw will bend under pressure or cause the material to not work properly or to what you’re bumping with the end of the screw with that sticks out too far; this lists the nail in the coffin. Furthermore, there is also damage from stripping the head off the screw, especially for soft materials like wood or aluminum. Cross-threading also results from using the wrong screw in the first place. When you are screwing, be sure to start the screw at a true right angle to the surface or material to which you are joining it.

The second part of the fourth problem of the broken long screw head may come from the way the screw is made. For example, in welding production, some manufacturers can’t make such long screws in one piece. So, they’ll make the head section, and they’ll make the rod section, and then they’ll weld the head on. The torque used might be beyond the range that the screw itself can withstand. Or, the screw might be hardened, but after the surface treatment of plating (like galvanizing), hydrogen won’t be removed in time, causing the long screw to fail from hydrogen embrittlement.

The best way to prevent long screw damage is by choosing custom screws that are tailored to your project’s needs. This includes selecting the correct length, material, and strength to ensure the screw can handle the forces and environmental conditions it will face. By using the right custom screws, you can avoid issues like bending, breaking, or stripping, ensuring that your project remains structurally sound and reliable.

Conclusion

Since the last century, Shi Shi Tong is a proven provider of custom precision-machined fasteners in a variety of distinctive materials which have improved properties over the commodity grade fasteners supplied by many fastener companies. We offer many different versions and styles of custom, lengthy screws in a variety of lengths with many different materials. Contact us right now to discuss your application and how a fastener supplier like Engineered Source can help with custom, unique screws.

|

Skype: kalyn qin M: +86 18818786322 Tel: +86 0755-27322278 Add: Building 9, Tantou First Industrial Zone, Songgang Street, Baoan, Shenzhen 518105, Guangdong Province, China |

10 月-12-2024

kalyn

+86 13143444311

+86 13143444311 sst@szsst88.com

sst@szsst88.com